| Sign In | Join Free | My esadidasol.com |

|

| Sign In | Join Free | My esadidasol.com |

|

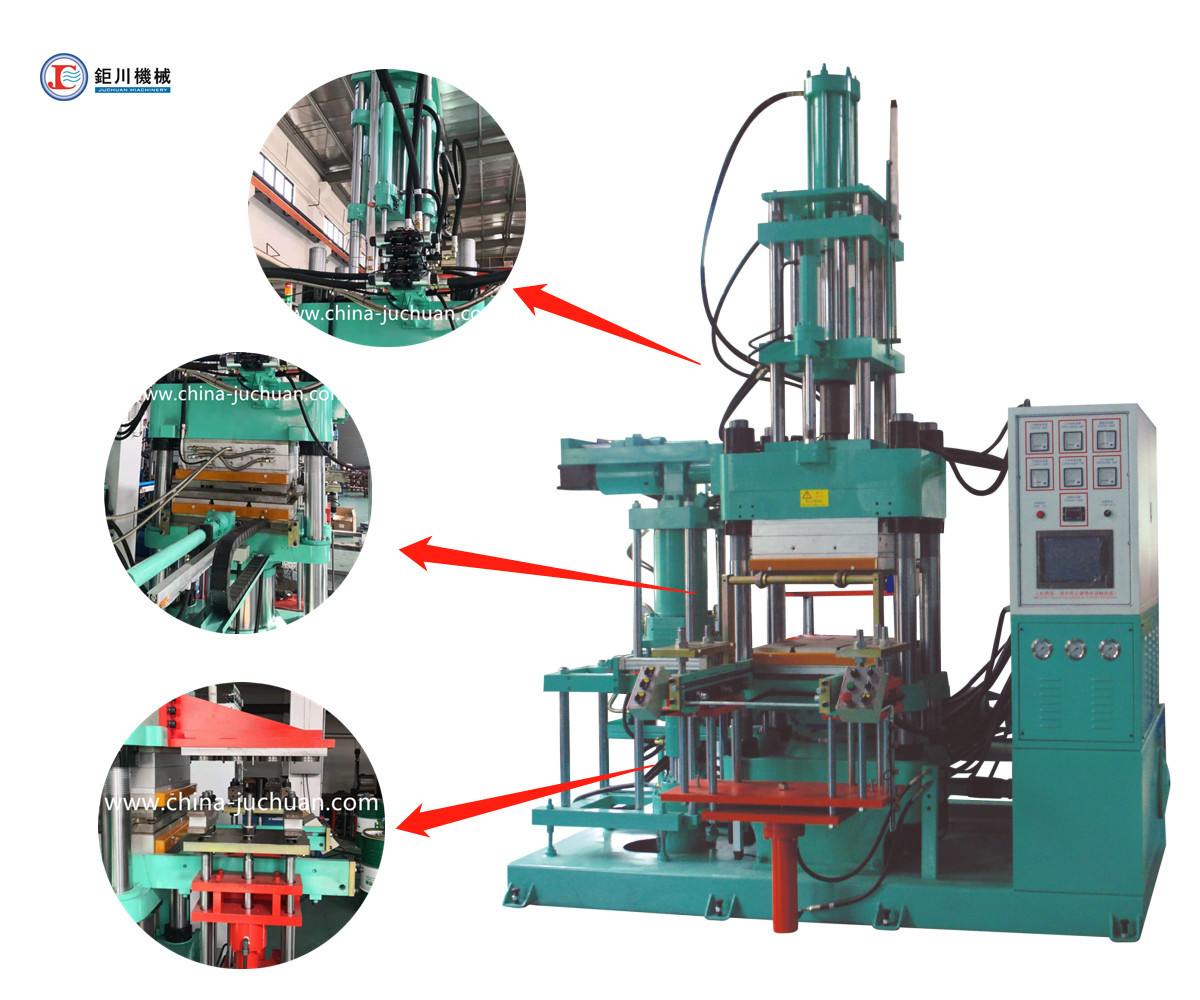

| Categories | Silicone Rubber Injection Molding Machine |

|---|---|

| Brand Name: | JUCHUAN |

| Certification: | SGS CE ISO9001:2015 |

| Place of Origin: | Guangdong China |

| MOQ: | 1set |

| Price: | USD 21800-40000one set |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 100 Set/Sets per Month |

| Delivery Time: | 45 days |

| Model Number: | JC-VI-AO |

| Packaging Details: | Fixed with hard straps |

| Clamp Force(Ton): | 50-400 |

| Injection Volume(cc): | 500-4000 |

| Injection Pressure(kgf/cm2): | 1800 |

| Platen Size(mm): | 300*300-700*700 |

| Plunger Diameter(mm): | 250-500 or Customized |

| Min. Mold Thickness(mm): | 50-100 |

| Plunger Stroke(mm): | 300-500 |

| Heating Plates Distance(mm): | 350-600 |

| Tie Bar Distance(mm): | 400*140-820*395 |

| Mold Opening Type: | 2RT-3RT-4RT-Upper Hanging Die-Lower Hanging Die |

| Max. Operating Pressure: | 20 |

| Motor Power(KW): | 5.5-11 |

| Heating Power(KW): | 8.4-24 |

| Total Power(KW): | 13.9 - 35 |

| Gross Weight(Ton): | 5.5-10 |

| Machine Size L*W*H(mm): | 2000*1500*2800 - 2750*2265*4200 |

| Plate Size: | 550x560mm | Clamp Force: | 200 Ton |

|---|---|---|---|

| Applications:: | Automotive Rubber Parts | Injection Structure: | All-in-all-out Injection Structure |

| Technoloyu: | Complete Intellectual Property Rights | Material Apply: | Silicone Or Rubber |

| Voltage: | AC380V | Material: | Solid Silicone |

| High Light: | hydraulic power press machine,hydraulic oil press machine | ||

Main Problems of Rubber Injection Molding Machine:

Rubber Injection Machine Development Trendency:

Main Technical Parameters:

| Model | Unit | 50VI-AO | 100VI-AO | 200VI-AO | 300VI-AO | 400VI-AO | 600VI-AO | 800VI-AO | 1000VI-AO |

| Clamping Force | Ton | 50 | 100 | 200 | 300 | 400 | 600 | 800 | 1000 |

| Injection Capacity | cc | 500 | 500 | 2000 | 3000 | 4000 | 6000 | 8000 | 10000 |

| Injection pressure | kgf/cm² | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 |

| Operation table size | mm | 300*300 | 400*400 | 550*560 | 700*700 | 700*700 | 850*850 | 1000*1000 | 1200*1200 |

| Min. Mold Thickness | mm | 50 | 50 | 100 | 100 | 100 | 100 | 150 | 150 |

| Plunger stroke | mm | 300 | 350 | 400 | 400 | 400 | 500 | 500 | 500 |

| Distance of Thermo-plate | mm | 350~450 | 400~500 | 500~600 | 500~600 | 500~600 | 600~700 | 650~800 | 650~800 |

| Distance of Tie bar | mm | 400*140 | 515*230 | 640*310 | 820*395 | 820*395 | 970*500 | 1140*600 | 1340*800 |

| Die sinking type | 2RT-3RT-4RT-Upper Mold-Lower Mold | ||||||||

Max. Operating Pressure | Mpa | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Motor Power | hp | 7.5 | 10 | 15 | 15 | 15 | 20 | 20 | 25 |

| Electric Heating Power | Kw | 8.4 | 10 | 15.3 | 24 | 24 | 29.75 | 35 | 42 |

| Total Power | Kw | 16.9 | 20.5 | 30.3 | 39 | 39 | 48.75 | 54 | 64.5 |

| Gross weight | Ton | 5.5 | 6 | 7.5 | 9 | 10 | 14.2 | 17.5 | 21 |

Dimension (L*W*H) | mm | 2000*1500 *H2800 | 2400*1650 *3200 | 2600*2000 *4000 | 2750*2265 *4200 | 2750*2265 *4200 | 3200*2500 *4350 | L3450*W2750 *H4500 | 3750*3050 *5000 |

Reference Images:

|

|