| Sign In | Join Free | My esadidasol.com |

|

| Sign In | Join Free | My esadidasol.com |

|

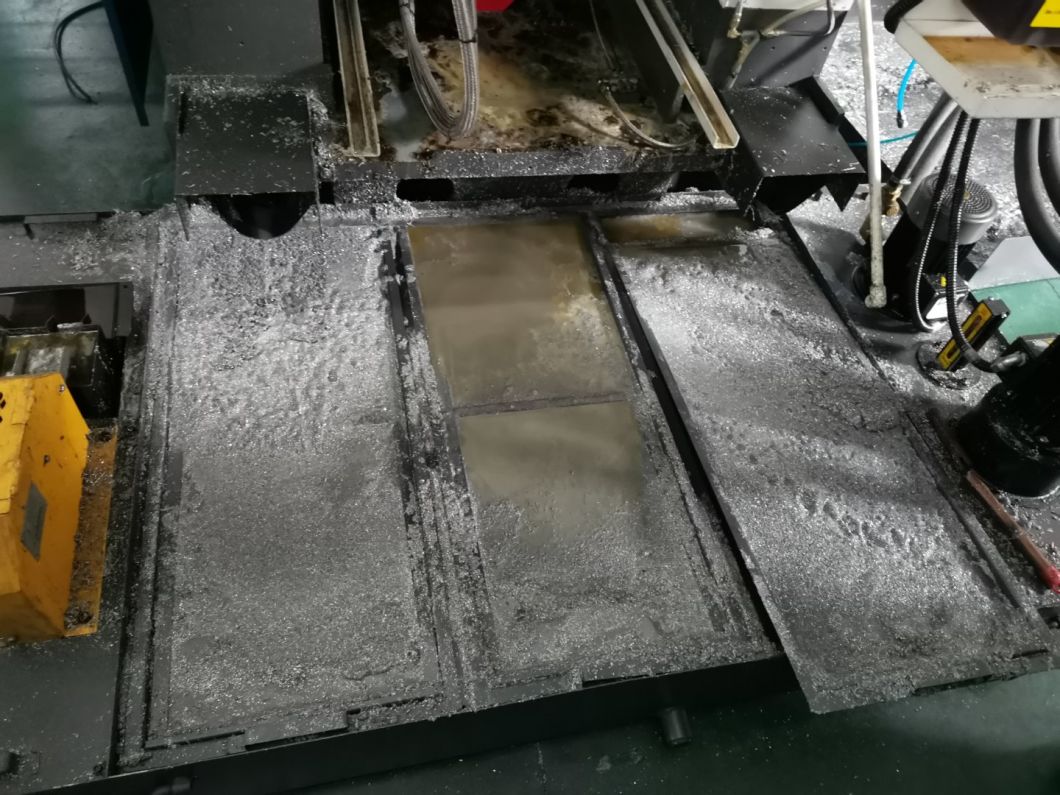

| Categories | CNC Coolant Tank Cleaner |

|---|---|

| Brand Name: | Diang Tianke |

| Place of Origin: | China |

| Price: | Negotiable |

| Payment Terms: | LC, T/T, PayPal, Western Union, Small-amount payment, Money Gram |

| Delivery Time: | 7-15 workdays |

| Installation: | Not Have |

| Centrifuge Type: | Not Have |

| Distillation Equipment Type: | Not Have |

| Extraction Tower Type: | Not Have |

| Pressure: | High Pressure |

| Condition: | New |

| Equipment Weight: | 108kg |

| Working Air Pressure: | 0.2-0.5MPa |

| Working Voltage: | AC220V |

| Flow: | 8000L/H |

| Transport Package: | Wooden Box |

| Specification: | 790*530*1000mm |

| Trademark: | datk |

| Origin: | China |

| After-sales Service: | Life |

| Warranty: | One Year |

| Type: | Centrifuge |

| Object: | Cutting Fluid |

| Separation Mode: | Filter Type |

| Operating Type: | Continuous Type |

Equipment parameters

| Product size | 790 * 530 * 1000mm | Packaging wooden box size | 950 * 650 * 1100mm |

| Equipment weight: about | 108kg | Inlet diameter | 38mm |

| Outlet diameter | 45mm | Inlet diameter | 10mm |

| Working pressure | 0.2-0.5Mpa | Working voltage/power | 220V/3kw |

| Filtering accuracy | 0.75mm (customizable) | Wet extraction flow rate | 7000-8000L/H |

| Maximum dry suction force | -0.04MPa |

Principle of dry suction function of liquid tank cleaning machine:

The structure of the liquid tank cleaning machine with dry suction

function is equipped with multiple detachable heads, filtration

systems, vacuum buckets, and vacuum hoses. Turn on the power, the

vacuum pump rotates, and the air inside the device is drawn out,

generating pressure. Due to the pressure difference, the suction

port of the machine body will have airflow flowing into the bucket,

while also bringing in garbage. After being filtered by the system,

the garbage is left in the vacuum cleaner and the clean liquid is

discharged.

main features

main features

Simple structure and fast cleaning speed: The liquid tank cleaning

machine has a compact design, high cleaning efficiency, and can

quickly complete the pumping and cleaning of a large amount of

cutting fluid.

Easy to maintain: This device has low maintenance costs and can

operate stably for a long time, reducing the maintenance burden on

enterprises.

Efficient filtration: Adopting a multi-stage filtration device, it

can filter out metal cutting and other impurities in the cutting

fluid while pumping, achieving solid-liquid separation.

Multifunctional: It can not only be used for purifying cutting

fluids and cleaning oil sludge and debris in storage tanks, but

also as a cleaning equipment for liquid fluids such as water and

oil splashed out in machining workshops.

Energy saving and environmental protection: By purifying and

treating emulsions online, recycled water can be recycled and

reused, reducing the total amount of emulsion emissions, lowering

enterprise emission costs, and saving freshwater resources.

Our strength:

1, Striving for excellence and putting service first: exploring the

application field of cutting fluid and continuously creating value

for customers;

2, Strong research and development capabilities: With over 10 years

of experience in the industry, we provide technical support and

services to customers, offering machining solutions and technical

support;

3, Strict quality management system: All of our products accept

customized services with the goal of providing customers with

high-quality products;

4, Perfect after-sales service: sufficient production capacity,

guaranteed delivery time, perfect supervision ability, and

guaranteed quality.

|