| Sign In | Join Free | My esadidasol.com |

|

| Sign In | Join Free | My esadidasol.com |

|

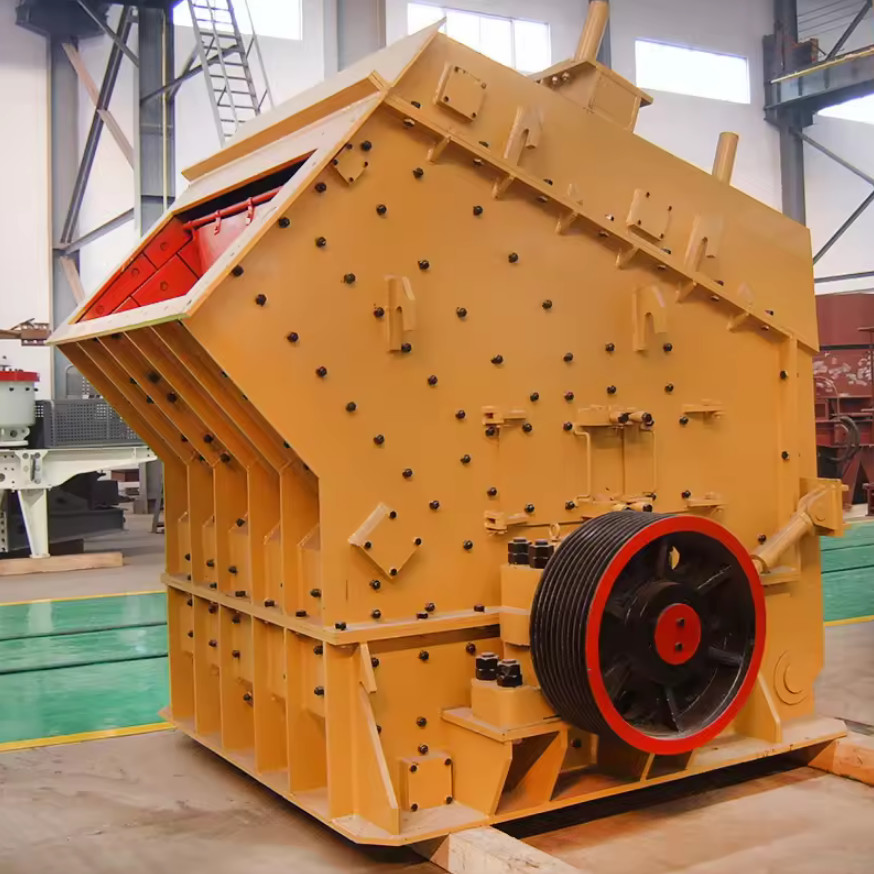

| Categories | Impact Stone Crusher Machine |

|---|---|

| Brand Name: | Ascend |

| Model Number: | PF-1008 PF-1010 PF-1210 PF-1212 PF-1214 PF-1315 |

| Certification: | ISO9001 |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | USD 5999-6999 |

| Payment Terms: | T/T, L/C, , D/A |

| Supply Ability: | 50 Sets per month |

| Delivery Time: | 7-15 working days |

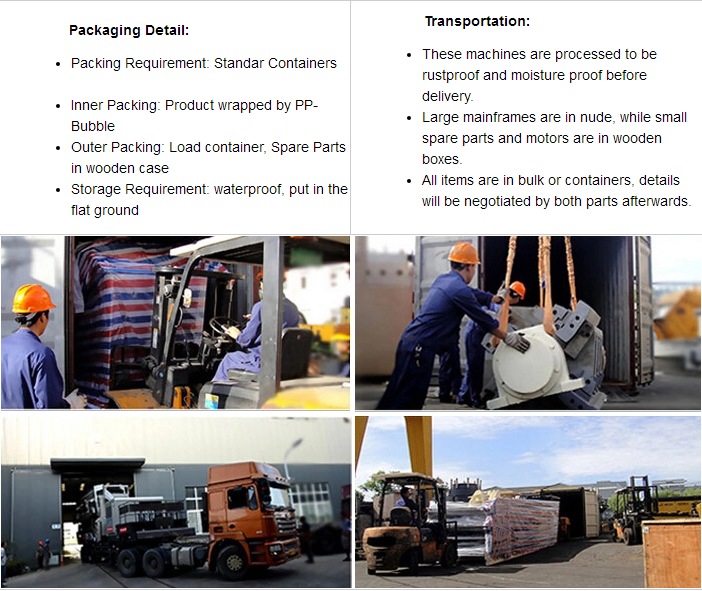

| Packaging Details: | Wooden box or put in container |

| Type: | Impact Crusher |

| Discharge Size: | 0-40mm |

| Color: | Customizable |

| Spare Parts: | long-term supply, sufficient |

| Warranty: | 1 Year |

| Keywords: | Impact Stone Crusher Machine |

| Input Size: | <100mm, <500mm |

| Founction: | primary crushing or secondary crushing |

| Application: | Crushing stones |

| Material: | Limestone, granite, basalt, river stone, etc. |

| Usage: | Mining And Building |

| Motor Type: | AC Motor |

| Weight: | 8-50t |

| Power Source: | Electric |

| Condition: | New |

| Company Info. |

| Henan Ascend Machinery Equipment Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

impact crusher for granite rock construction waste crushing

Impact Crusher can crush the large, medium and small size materials (granite, limestone, concrete ,etc.)With max feed size less than 500mm and compression strength less than 350Mpa.It is widely used in metallurgy, mine, cement, chemical engineering, fire resistant materials, ceramics and other industrial sectors, as well as in the expressway construction, water conservancy project, building crushed stone, and machine-made sand process fields, etc.Presently, by practices, its comprehensive function is superior to the cone crusher and the hammer crusher.

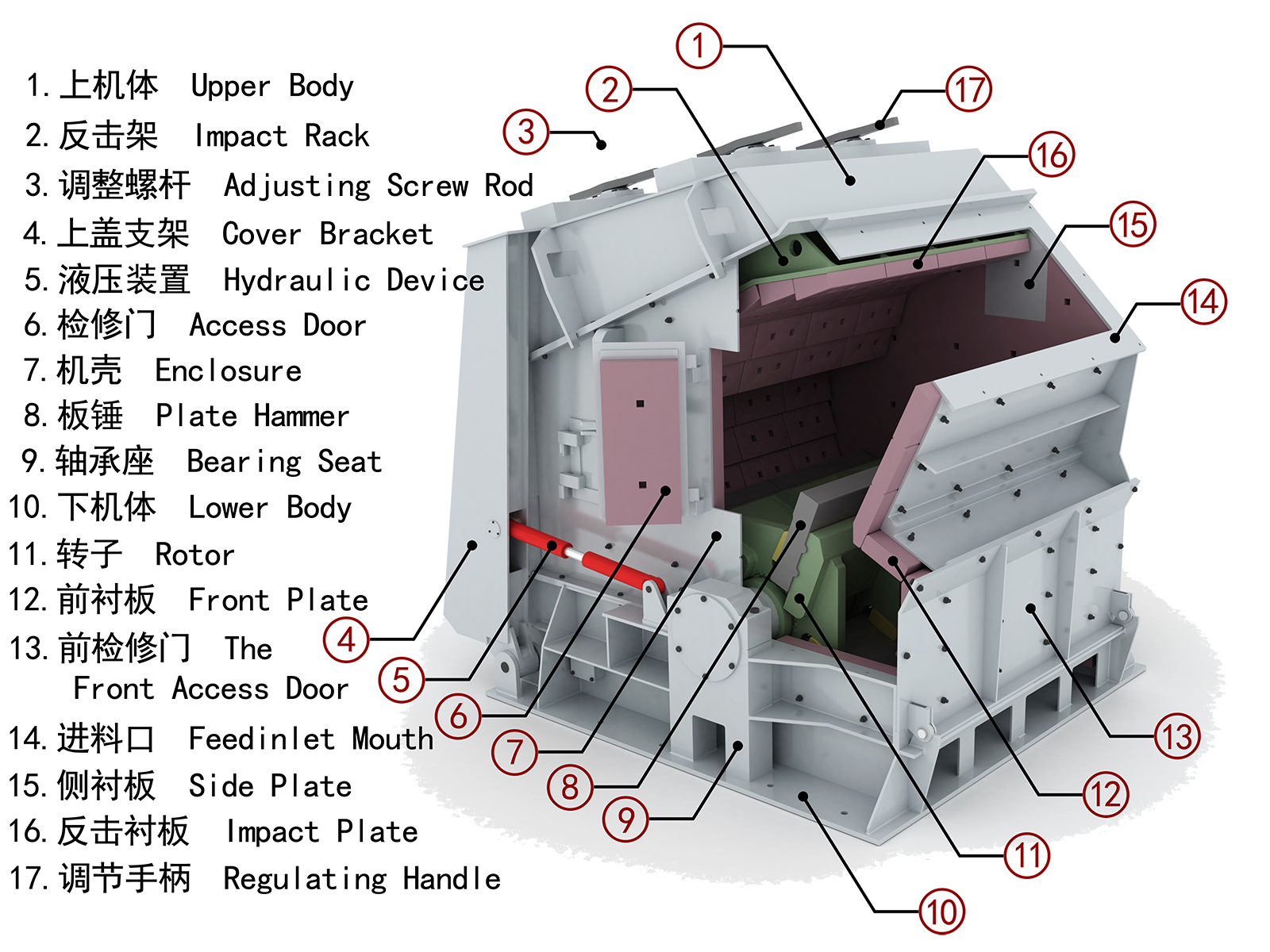

Working principle

Impact crusher has two series: two-cavity and three-cavity impact crusher. It is a kind of crushing equipment using impact energy to crush material driven by motor. When the materials get into the area where the plate hammer effects, by whose high speed impact function, the crushed materials are thrown to the impact device above the rotor continuously, and then they are rebounded from the impact liner to the effect area of the blow bar to be crushed again. The materials are crushed from big-size to small-size in the impact cavity repeatedly. The process goes on until the materials are crushed to the required size and then discharged from the down part of the machine.

spare parts

Specifications

| Model | Size of rotor (mm) | Feed opening (mm) | Max. feed size (mm) | Capacity (t/h) | Power of Motor (kW) | Weight (t) |

| PF1010 | Φ1000×1050 | 400×1080 | 350 | 50-80 | 75 | 12.5 |

| PF1210 | Φ1250×1050 | 400×1080 | 350 | 70-130 | 110 | 16.5 |

| PF1214 | Φ1250×1400 | 400×1430 | 350 | 90-180 | 132 | 19 |

| PF1315 | Φ1320×1500 | 860×1520 | 500 | 120-250 | 200 | 24 |

| PF1320 | Φ1320×2000 | 860×2030 | 500 | 160-350 | 260 | 27 |

Application

PF impact crusher is usually used as secondary or tertiary crusher to crusher the not less harder materials with Mosh hardness less than 5.5, the following materials is the favourite of impact crusher.

|

|

packaging & shipping

|