| Sign In | Join Free | My esadidasol.com |

|

| Sign In | Join Free | My esadidasol.com |

|

| Categories | SMT Spare Parts |

|---|---|

| Brand Name: | smtline |

| Model Number: | L-type PCB downloader |

| Certification: | YAMAHA Vibration Vibration Fit YV YS |

| Place of Origin: | China |

| MOQ: | 1 |

| Price: | negotiation |

| Payment Terms: | T/T,Western Union,paypal |

| Supply Ability: | 10pcs/day |

| Delivery Time: | 1-2 work days |

| Packaging Details: | Woodenbox |

| Brand: | SMTLINE |

| Model: | L-type PCB downloader |

| Capayity: | 1009 |

| Mounter Weight: | 0.79kg |

| Mounter Size: | 56 |

| Supplier: | SMTLINE |

| Condition: | new |

| Company Info. |

| Shenzhen CN Technology Co. Ltd.. |

| Verified Supplier |

| View Contact Details |

| Product List |

Our company has been in operation for 11 years and will definitely

be your best choice with guaranteed quality and fast delivery

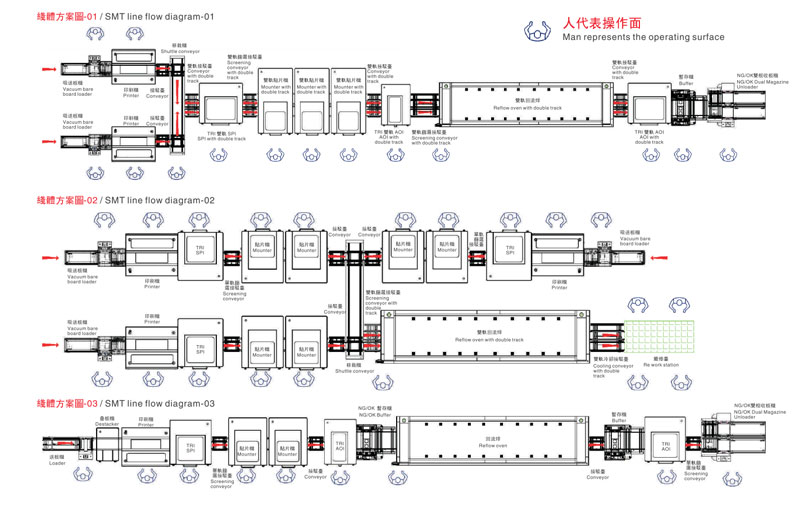

Product Introduction – L-type PCB Downloader (Unloader)

The L-type PCB Downloader, also known as an L-type PCB Unloader, is used at the end of an SMT production line to automatically unload finished PCBs into storage magazines. Its L-shaped structure positions the magazine rack perpendicular to the conveyor, saving floor space and allowing easier magazine handling in compact environments.

Key Features

L-shaped magazine orientation: Optimizes floor layout by placing

magazines at a 90-degree angle to the conveyor.

Fully automatic unloading: Transfers PCBs from the conveyor into

magazine slots using a push-arm and lift system.

Touch screen operation: Intuitive HMI for setting operating modes,

lift control, and diagnostics.

Programmable slot control: Supports empty-slot skip, adjustable

unloading pitch, and full magazine detection.

SMEMA-compatible: Enables inline communication with AOI, reflow, or

inspection equipment.

Safe and stable design: Aluminum frame with ESD-safe construction,

emergency stop button, and protective covers.

Technical Specifications

| Item | Specification |

| Model | L-Type PCB Downloader / Unloader |

| PCB Size Range | 50 × 50 mm to 330 × 250 mm (customizable) |

| Magazine Size | 355 × 320 × 563 mm (standard) |

| Cycle Time | Approx. 6 seconds/PCB |

| Conveyor Height | 900 ± 20 mm |

| Transport Direction | Left to right or right to left |

| Air Supply | 4–6 kg/cm² |

| Power Supply | AC 220V, 50/60Hz |

| Control System | PLC + Touchscreen |

| Weight | Approx. 180–250 kg |

Applications

End-of-line PCB unloading in SMT/EMS production lines

Commonly used after reflow ovens, AOI, functional testers

Suitable for rigid, semi-flex, or LED PCBs

Related Accessories – L-Type PCB Downloader / Unloader

1. Magazine & Handling Accessories

| Accessory | Description |

| Standard PCB Magazine | 355×320×563 mm or 390×320×570 mm, ESD-safe frame |

| Magazine Clamp Set | Holds the magazine securely on the lift platform |

| Magazine Lift Platform | Electric-driven platform for vertical movement of the magazine |

| Magazine Push Arm | Transfers PCB from conveyor into magazine slot |

2. Mechanical Components

| Accessory | Description |

| Guide Rail (Adjustable) | For smooth PCB alignment and stable transfer |

| PCB Stopper | Stops PCB at correct push-in point; sensor-activated |

| Frame Panels / Covers | ESD-safe aluminum side panels and top covers |

| Conveyor Belt or Chain | Anti-static conveyor segment for PCB transfer |

| Adjustable Support Feet | Height adjustment and leveling for conveyor height |

3. Electrical & Control Components

| Accessory | Description |

| PLC Controller | Typically from Mitsubishi, Siemens, or Omron |

| Touch Screen (HMI) | 7-inch or 10-inch for user interface and settings |

| Photoelectric Sensors | Detect PCB arrival, magazine slot status, or empty condition |

| Emergency Stop Switch | Operator safety — instantly halts machine |

| Power Switch / Main Breaker | Controls AC input; includes fuse circuit |

| SMEMA Interface Cable | Communicates with upstream machines (AOI, reflow, etc.) |

4. Pneumatic Accessories

| Accessory | Description |

| Air Cylinder (Pusher Arm) | Drives PCB into magazine slot |

| Solenoid Valve | Directs air flow to cylinder; 5/2-way common type |

| FRL Unit (Filter + Regulator + Lubricator) | Ensures clean, regulated air supply |

| Pneumatic Tubing (6mm/8mm) | Anti-static air tubes for all air systems |

5. Maintenance Tools & Safety Accessories

| Accessory | Description |

| Lubrication Oil | For linear guide maintenance (VG32 or equivalent) |

| Cleaning Tools | Anti-static brush, air blower, ESD cloth |

| Spare Fuse Kit | For main power control unit |

| Tool Kit | Hex keys, screwdrivers, spanner set |

| Safety Light Curtain (optional) | Enhances operator protection around the working zone |

6. Optional Upgrades

| Accessory | Description |

| Barcode Scanner Mount | For inline product tracking integration |

| Full Magazine Alarm Light | Signal tower to indicate magazine change required |

| Custom Magazine Adapter | For non-standard board or carrier sizes |

Related Part Numbers – L-Type PCB Downloader / Unloader

1. Magazine & Handling Parts

| Part Name | Description |

| Standard PCB Magazine | 355 × 320 × 563 mm (standard size) |

| Large PCB Magazine | 390 × 320 × 570 mm |

| Magazine Clamp Set | Clamping mechanism for securing magazine |

| Lift Platform Assembly | Motorized vertical lift unit |

2. Mechanical Components

| Part Name | Description |

| Push Arm Assembly | Pneumatic push arm |

| Guide Rail (adjustable) | Aluminum rail, ESD-safe, 250 mm length |

| PCB Stopper (Sensor Type) | Stops PCB before loading into magazine |

| Conveyor Chain/Belt | 6 mm wide ESD-safe belt |

| Adjustable Feet | Anti-vibration leveling foot, M12 thread |

3. Electrical & Control Components

| Part Name | Description |

| PLC Controller (Mitsubishi) | 24 I/O, used in many unloader models |

| Touchscreen HMI (Weinview) | 7” screen for operator control |

| Photoelectric Sensor | Position detection (PCB or slot) |

| Emergency Stop Button | 22 mm twist-type red emergency switch |

| SMEMA Communication Cable | 10-pin interface cable for inline comms |

4. Pneumatic Accessories

| Part Name | Description |

| Air Cylinder (Pusher) | Compact air cylinder, 32 mm bore, 50 mm stroke |

| Solenoid Valve | 5/2-way double coil |

| FRL Unit | Filter + Regulator + Lubricator unit |

| Air Tubing (6 mm) | Black ESD-safe PU tubing |

5. Maintenance & Optional Components

| Part Name | Description |

| Lubrication Oil | For guide rail and lift mechanism |

| Safety Light Curtain | Optional safety barrier |

| Signal Tower Light | Red/Green/Yellow stack light, 220V |

| Barcode Scanner Mount | Mounting bracket for inline scanner |

| Spare Fuse Kit | 5A, 220V fuses with fuse holders |

FAQ Guide – L-Type PCB Downloader / Unloader

1. What is the L-type PCB Downloader used for?

The L-type PCB Downloader (also called PCB Unloader) is used at the end of the SMT production line to automatically receive and unload finished PCBs from the conveyor into storage magazines. It ensures safe, efficient handling of completed boards.

2. Why is it called “L-type”?

Because the magazine rack is positioned at a 90° angle (perpendicular) to the PCB conveyor direction, forming an L-shape. This layout saves floor space and allows better access for operators.

3. What kinds of PCBs can it unload?

Standard rigid PCBs

LED light boards

Aluminum or fiberglass (FR4) boards

PCB size typically from 50 × 50 mm to 330 × 250 mm (customizable)

4. What are the compatible magazine sizes?

355 × 320 × 563 mm (standard)

390 × 320 × 570 mm (optional)

Custom magazine sizes are supported upon request

5. What are the main features?

L-shape magazine placement for compact line layout

Fully automatic PCB loading into magazines

Touch screen + PLC control system

Programmable slot pitch and skip-empty function

SMEMA interface compatible

Safety interlocks and emergency stop button

Aluminum frame with anti-static surface

6. What is the cycle time per PCB?

Around 6–10 seconds per board, depending on board size and push speed

7. What safety functions are included?

Emergency stop switch

Enclosed covers over moving parts

Error alarms and buzzer

Optional: Safety light curtain (for operator protection)

8. What are the main replaceable parts?

Push arm assembly

Lift motor or cylinder

Sensors (photoelectric or slot detection)

Touch screen panel

Solenoid valve and pneumatic tubing

Magazine clamps and guide rails

9. What maintenance is required?

Daily: Clean conveyor, check for loose parts

Weekly: Inspect sensors and push mechanism

Monthly: Lubricate lift guide and check air pressure system

As needed: Replace worn parts (belts, cylinders, fuses)

10. Can it be integrated with MES or barcode systems?

Yes. Many models support integration with:

MES data collection

Inline barcode scanners

Traceability systems

11. Is customization available?

Yes. You can request:

Magazine size changes

Conveyor width customization

Additional I/O ports or network modules

External signal tower or buzzer

pcb magazine loader,pcb loader,smt loader,pcb loader machine,bare

board loader,pcb loader unloader,pcb magazine unloader,smt

conveyor,pcb inspection conveyor,pcb conveyor,pcb magazine,pcb

magazine rack,smt magazine rack,magazine pcb,smt magazine,smd

magazine,pcb storage racks,pcb container,ESD storage racks,esd pcb

racks,smd counter machine,reel counter machine,component counting

machine,smd component counter ,smd parts counter ,nozzle cleaning

machine

Contact:

CNSMT Electronics Equipment Co,.LTD

Email: info@smtlinemachine.com

www.smtlinemachine.com

Mb/whatsapp/wechat:+8613537875415

SKYPE:smtdwx

|