| Sign In | Join Free | My esadidasol.com |

|

| Sign In | Join Free | My esadidasol.com |

|

| Categories | Micro Boring Tool |

|---|---|

| Place of Origin: | Shenzhen,China |

| Brand Name: | Inrover |

| Model Number: | MGSR |

| Packaging Details: | Plastic tubes+ Carton Box |

| MOQ: | 5 |

| Price: | Please Contact Supplier |

| Payment Terms: | T/T |

| Supply Ability: | 30000pcs/month |

| Delivery Time: | 5-15 days |

| Warranty: | 3 years, 3 years |

| Customized support: | OEM, ODM, OBM |

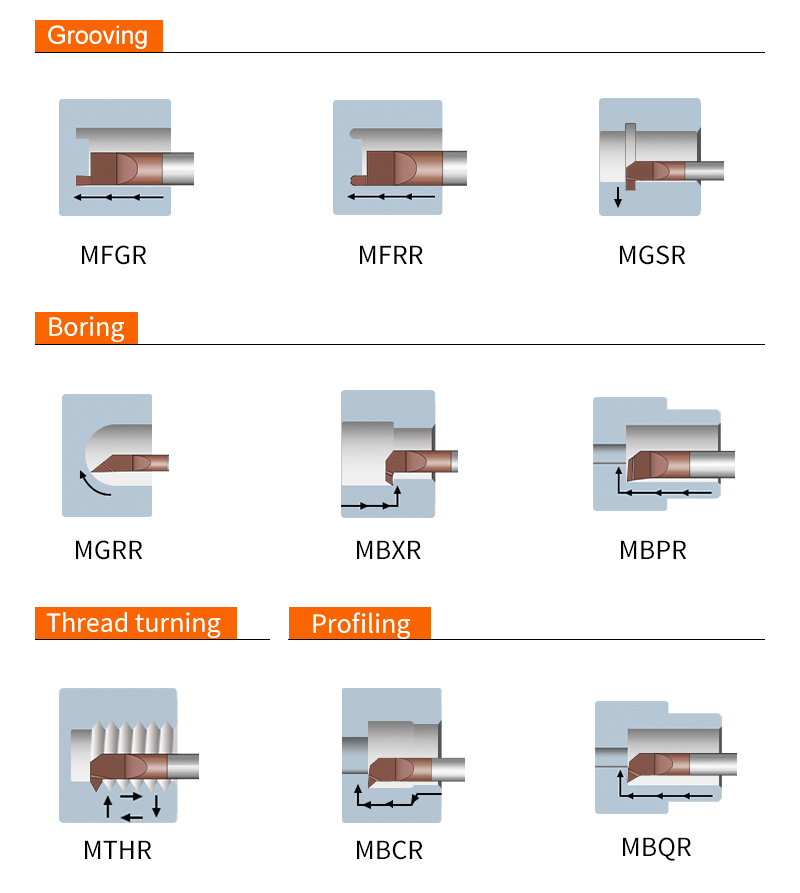

| Usage: | Internal Turning Tool |

| Hardness: | HRC 91-93.5, HRA 91-93.5 |

| Coating: | To be defined, With or without coat, Nano coating |

| Application: | Internal Turning Tool |

| Color: | bronze, matte |

| MOQ: | 1pcs |

| Model: | MGSR |

| OEM & ODM: | Acceptable |

| Material: | 100% Virgin Tungsten Carbide |

| Product name: | Inner hole grooving tool |

| Grade: | ISO Grades |

| Certification: | ISO9001 |

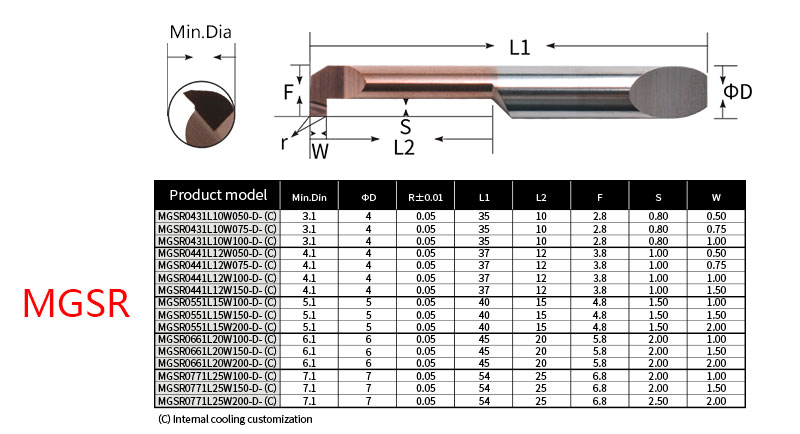

High Efficiency Tungsten Internal Grooving Tools Turning Machining HRC60 Small Inner Hole Grooving Width 0.5-2.0 Depth

Specification

| Type | Inner hole grooving | |||

| Product name | MGSR tungsten carbide Inner hole grooving tool | |||

| Brand Name | INROVER | |||

| Material | Tungsten Carbide | |||

| Precision | ±0.005mm | |||

| Coating | Nano coating | |||

| Weight of item(WT) | 0.02kg | |||

| Machining type | Turning Tool | |||

| Product color | Bronze, Matte | |||

| cutting depth | 0.05-0.5mm | |||

| Feed rate | 0.03-0.1mm/r | |||

| Linear velocity Vc | 20-100m/min | |||

| Suitable for machine tools | CNC lathes, centering machines, cutter arranging machine skateboard lathes,turret lathes and other longitudinal lathes | |||

| Mainly suitable for machine tool brands | Swiss TORNOS lathe, Citizen, Nomura, Tsugami,Star,Miyano,etc | |||

| Product Features | 1. Smooth chip evacuation and efficient machining | |||

| 2. The boring tool is integrally formed | ||||

| 3. Imported machine tool precision grinding | ||||

| 4. Nano coating is wear-resistant and durable | ||||

| 5. Calibration-free design is efficient and convenient | ||||

| Rigorous quality inspection | 1.Projector detection | |||

| 2.ZOLLER detection | ||||

| 3.Swis edging | ||||

| 4.German forging difference process detection | ||||

| 5.Edge passivation detection | ||||

| 6.Coreless grinding | ||||

|