| Sign In | Join Free | My esadidasol.com |

|

| Sign In | Join Free | My esadidasol.com |

|

| Categories | Micro Boring Tool |

|---|---|

| Place of Origin: | Shenzhen,China |

| Brand Name: | Inrover |

| Model Number: | MBPR |

| Packaging Details: | Plastic tubes+ Carton Box |

| MOQ: | 5 |

| Price: | Please Contact Supplier |

| Payment Terms: | T/T |

| Supply Ability: | 30000pcs/month |

| Delivery Time: | 5-15 days |

| Certification: | ISO9001 |

| Customized support: | OEM, ODM, OBM |

| Usage: | Internal Turning Tool |

| Hardness: | HRC 91-93.5 |

| Coating: | To be defined, With or without coating, Nano coating |

| Material: | Tungsten Carbide |

| Tip arc: | R0.05-R0.20 |

| Penetration depth: | 0.2mm-0.7mm |

| Shank diameter: | 4mm-7mm |

| Machining type: | Boring Tool |

| Shank Type: | rear end tilt |

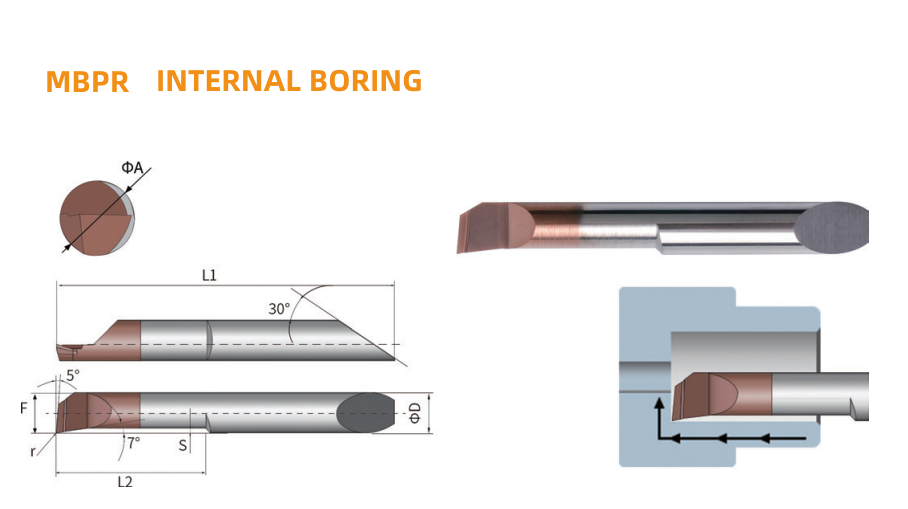

Quick Change Micro Bore Cutter For Mini Turning Lathe Small Hole Solid Cabide Boring Bar For Internal Machine

| Model | ΦA | ΦD | r | L1 | L2 | F | S |

MBPR0421L06R005-Y | 2.1 | 4 | 0.05 | 31 | 6 | 1.85 | 0.2 |

MBPR0421L06R010-Y | 2.1 | 4 | 0.1 | 31 | 6 | 1.85 | 0.2 |

MBPR0421L10R005-Y | 2.1 | 4 | 0.05 | 35 | 10 | 1.85 | 0.2 |

MBPR0421L10R010-Y | 2.1 | 4 | 0.1 | 35 | 10 | 1.85 | 0.2 |

MBPR0426L08R005-Y | 2.6 | 4 | 0.05 | 33 | 12 | 2.35 | 0.25 |

MBPR0426L08R010-Y | 2.6 | 4 | 0.1 | 33 | 12 | 2.35 | 0.25 |

MBPR0426L08R015-Y | 2.6 | 4 | 0.15 | 33 | 12 | 2.35 | 0.25 |

MBPR0426L12R005-Y | 2.6 | 4 | 0.05 | 37 | 10 | 2.35 | 0.25 |

MBPR0426L12R010-Y | 2.6 | 4 | 0.1 | 37 | 10 | 2.35 | 0.25 |

MBPR0426L12R015-Y | 2.6 | 4 | 0.15 | 37 | 10 | 2.35 | 0.25 |

MBPR0431L10R005-Y | 3.1 | 4 | 0.05 | 35 | 10 | 2.8 | 0.3 |

MBPR0431L10R010-Y | 3.1 | 4 | 0.1 | 35 | 10 | 2.8 | 0.3 |

MBPR0431L10R015-Y | 3.1 | 4 | 0.15 | 35 | 10 | 2.8 | 0.3 |

MBPR0431L15R005-Y | 3.1 | 4 | 0.05 | 40 | 15 | 2.8 | 0.3 |

MBPR0441L12R005-Y | 4.1 | 4 | 0.05 | 37 | 12 | 3.8 | 0.4 |

| ... | ... | ... | ... | ... | ... | ... | ... |

MBPR0771L35R020-Y | 7.1 | 7 | 0.2 | 64 | 35 | 6.8 | 0.7 |

| Please contact supplier for full specifications | |||||||

1. Small internal machining

2. Large tooling line-up for a wide application range

3. High-rigidity clamping prevents deviation

4. Long tool life and high machining efficiency

5. Minimum bore diameter: 2.1 – 7.1 mm

6. Selection of different chipbreakers for different purposes

7. High rake angle ensures stable machining without vibration and good chip evacuation

1,AlTiSiN (3300HV0.05,0.3,≥1100°)

2,Available for HRC≤65° materials : stainless; steel; KOVAR;

superalloy; titanium alloy; copper; iron casting and so on.

3,Each specification in catalog is full stocked.

4,Can customize for different coating,and it just need 2-3days

because of full stock non-coating products and mature coating

system,

5,Quick change

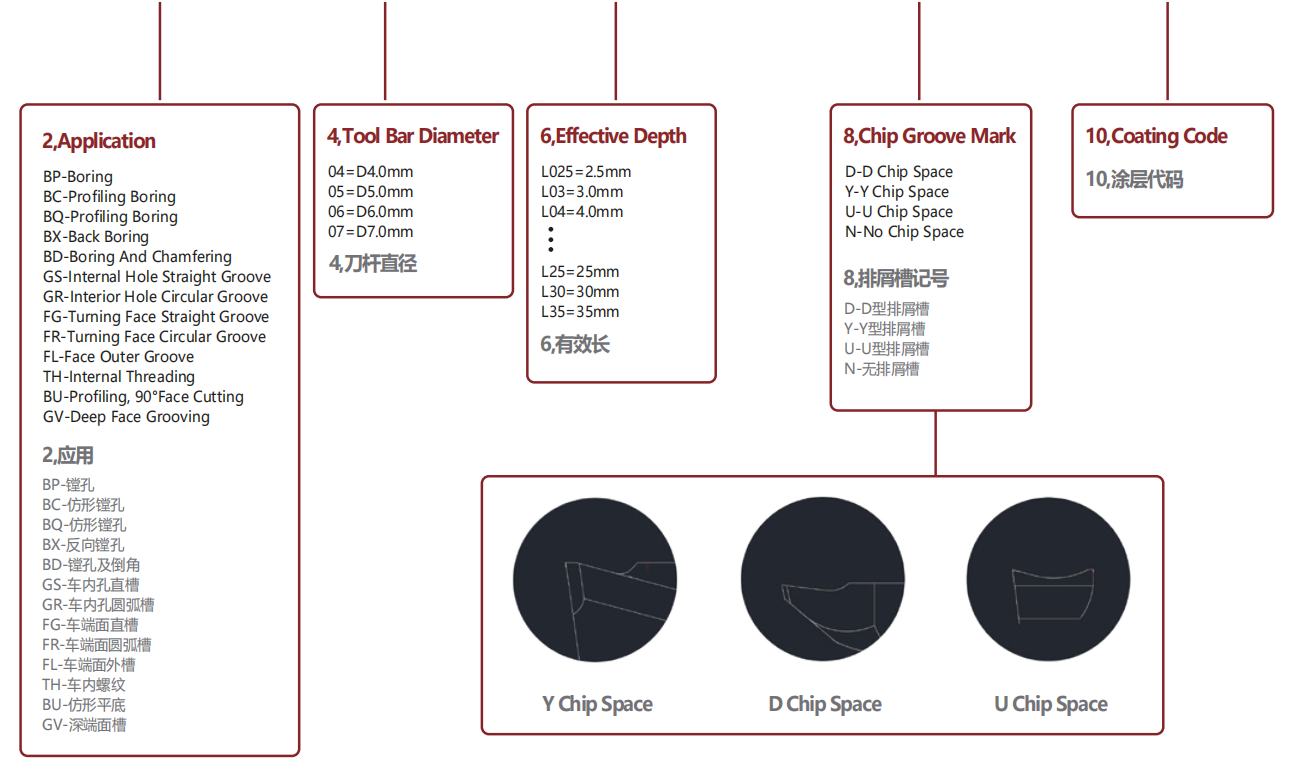

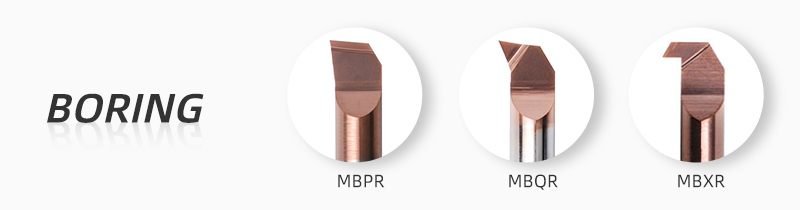

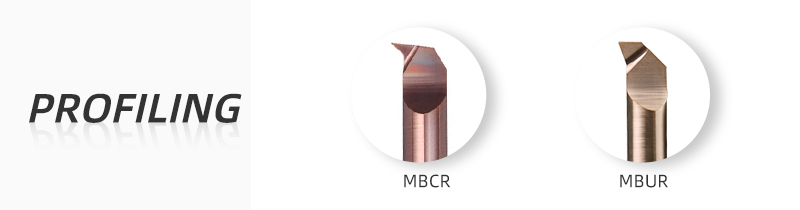

Different Types

MBPR : 80 degree angle design, 15° “Y”strong type chipbraker

MBQR : 60 degree angle design, 7°“D”sharp type chipbraker

MBXR : Designed for Back boring with "D"chipbraker

MBCR : 30 degree angle design, 7°“D”sharp type chipbraker

MBUR : Profiling,90° face cutting,7°“D”sharp type chipbraker

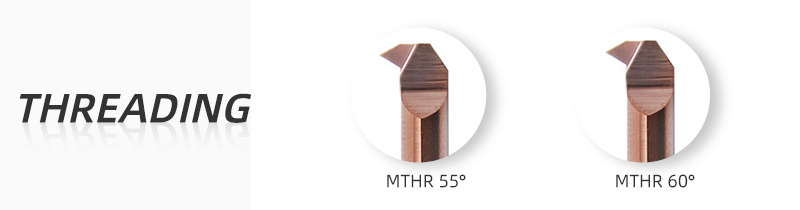

Thread MTHR 55°: Micro Threading tools with a 55 ° Internal threading profile for 3.1 mm Min.Bore Diameter

Thread MTHR 60°: Micro Threading tools with a 60° Internal threading profile for 2.0 mm Min.Bore Diameter

MGVR :Desighed for deep face grooving with U chipbreaker

MGSR : Desighed for face grooving with U chipbreaker

MFGR : Desighed for face grooving with U chipbreaker

|