| Sign In | Join Free | My esadidasol.com |

|

| Sign In | Join Free | My esadidasol.com |

|

| Categories | Laser Fume Extractor |

|---|---|

| Brand Name: | Waterun |

| Model Number: | XS700 |

| Certification: | CE |

| Place of Origin: | China |

| MOQ: | 1 |

| Price: | USD1100 ~ 1700 |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram, Paypal, Credit Card |

| Supply Ability: | 1000 units per month |

| Delivery Time: | 3-10 days |

| Packaging Details: | laser fume extraction 67 x 58 x 124cm 90kgs in Pallet |

| Name: | laser cutter fume extractor |

| Filters: | multiple 7 filters |

| Systemic Flow: | 750m3 per hour |

| Filtering Efficiency: | 99.97% 0.3 micron |

| Power: | 700W |

| Noise: | 63dB |

| Dimensions(mm): | 550 x 440 x 1060 mm |

| Aftersales Service: | Online Support |

XS700 Laser Marking Smoke Extractor 3D Printing Laser Cutting Fume Extractor

Description:

Waterun High negative pressure laser fume extractor has high filtration rate and big suction, which can make good performance for filtrate fumes, collect dust and absorb strong smell. It apply in air purification for co2 laser, fiber laser cutting/engraving, laser marking, soldering etc. Each laser smoke extractor are with LCD display, airflow can be adjustable both by key swich and remote control. It have warning system to remind customer to replace filters once filters blocked. And it can be customized to work with laser machine synchronously.This is the 7th generation fume extractor with constant airflow, vector control technology and quick filter replacement. Used DC brush-less motor which is high quality,long life span,high negative pressure and large flow.Multi-layers filters design ensure the best filtering effect.

Technical Datas:

| Model | XS450 | XS700 |

| Power | 450W | 700W |

| Noise | <60 dB | <63 dB |

| Systemic Flow | 700 m3/h | 750m3/h |

| Filter Layer | 8 | 7 |

| Filter Size | 1st Layer Fire Prevention Mesh 2nd Layer Pre-filter Cotton 28mm 3~4th Layer PP Filter 50mm 5th Layers Glass Fiber Filter 50mm 6~8th Layers Active Carbon Filter 50mm | 1st Layer Fire Prevention Mesh 2nd Layer Pre-filter Cotton 100mm 3~4th Layer PP Filter 50mm 5th Layers Glass Fiber Filter 100mm 6~7th Layers Active Carbon Filter 50mm |

| Gross Weight | 11kg | 13.5kg |

| Cabinet Dimensions | 550 x 440 x 885mm | 550 x 440 x 1035mm |

| Package Dimensions | Body:70 x 57 x 113cm | Body:64 x 53 x 125cm |

| Filtering Efficiency | 0.3um 99.97% | |

| Electrical | 110V / 220V | |

| Remote Control | Included | |

| Duct Dimension | Diameter 100mm x Length 2 meters | |

| Packing List | Main Unit: 1 piece Power Cord: 1 piece Tube Kits: 1 set Operation Instruction: 1 piece One Set Filters inside machine | |

Features:

1. With filter observation window, so you can view the filter

condition at any time;

2. Air inlet diversion design, increases the purification

efficiency by 80%;

3. The machine surface is made of metal, more corrosion resistance and

durable.

4. Brushless DC motor with stable performance, can work for 40K

hours consecutively.

5. Sound and light alarm to remind you to replace filters.

6. Microcomputer chip control,digital display and with the remote

control, you can operate it within 5 meters.

7. Provide trundle with brake, easy to move castors

8. Multilayer Filtration and rapid purification.

9. Noise reduction design, quiet operation

Applications:

This product is suitable for places involved in air pollution like smoke, peculiar smell, dust, poisonous and harmful gas,during the process of soldering, laser marking & carving,printing etc.

Additional Informations:

| Available Filter Efficiencies | Pre Filter For remove big particles of above 50 microns PP Filter/Glass Fiber Filter For particles above 0.3 microns, its filtering efficiency meet 99.97%. Active Carbon Filter For filtering hazardous gases with the filtering efficiency as high as above 95%; |

| Filter Replacement Period | Pr-Filter: 1 week to 2 month PP Filter/Glass Fiber Filter: 3-6 months Active Carbon Filter: 3-6 months However, it can be adjusted as per the exact pollutants generated in different Environment; |

FAQ:

1. What’s the functions for the filters?

Answers. 1) Pre-Filter/F8 pre-filter: the large-size pad filter can

filter large particles of dust (according the requirement to select

pre-filter or F8)

2) PP Middle Filter/Fiber glass filter: it filters the middle-size,

small size particles bigger powders for prolonging the main

filter's life. (according the requirement to select PP middle

filter or fiber glass filter,can use both, the efficiency better.)

3) Main Filter/Active carbon: it cleans harmful particles and

fumes.

4) High efficiency filter(combine middle filter and active carbon

filter): it can filter about 0.3micron particles and other harmful

fumes.

2. What’s the advantage compare with ducted exhaust fan?

Answer: 1. Many advantages like (1) Clean the air quality (2)

energy saving (3) easy installation, flexible remove (4) low cost

(5) reduce the incidence of diseases and major diseases, and health

is priceless (6) to reduce unpleasant smell (7) to reduce dust and

other harmful substances, and so on.

3. What’s the life span of our fume extractor?

Answer: Motor lifetime is (continuous working 24 hours) 20,000

hours, consider environmental factors. Usually it can use 4-5 years

without any problems.

4. The ducts for the fume extractor can be shortened or lengthened?

Answer: It can be shortened or lengthened appropriate; but we

suggest not more than 1.5meter. For multi-station, the total pipe

length should not exceed 10 meters.

5. What’s the best distance between the nozzle and the smokes?

Answer: The distance to be 5-15cm is the best.

6. How long need to to replace the pre-filter, middle filter and the

main filter?

Answer: 1. Pre-filter : normally needs to replace by 1 months

2. Middle filter: normally needs to replace by 3 months

3. Main filter: normally needs to replace by 6 months.

7. Bent pipe will affect smoke purify?

Answer: Yes, it affect the suction power, it should reduce the bent

rate.

8. Can our fume extractor completely filtered poison gas?

Answer: No, there still no any kind of filter can filter out 100%

of poison gas, but you can make a different filter net rate upon

request.

About Us:

Established in 2003, Waterun Technology is located in Shenzhen, China. We are a leading manufacturer & exporter of Fume Extractors,Soldering Robots,Screw Fastening Robots, Glue Dispensing Robots, ESD & Cleanroom products, Tools & Instruments for electronic assembly industry.

We own several brands: WATERUN, NEW OXYGEN, FUME GO, QUBO, etc.Waterun owns two factories and one business & logistics center and nearly 100 employees.Due to the good quality and good pricing, our products are getting popular in many countries in the world.

Our Quality:

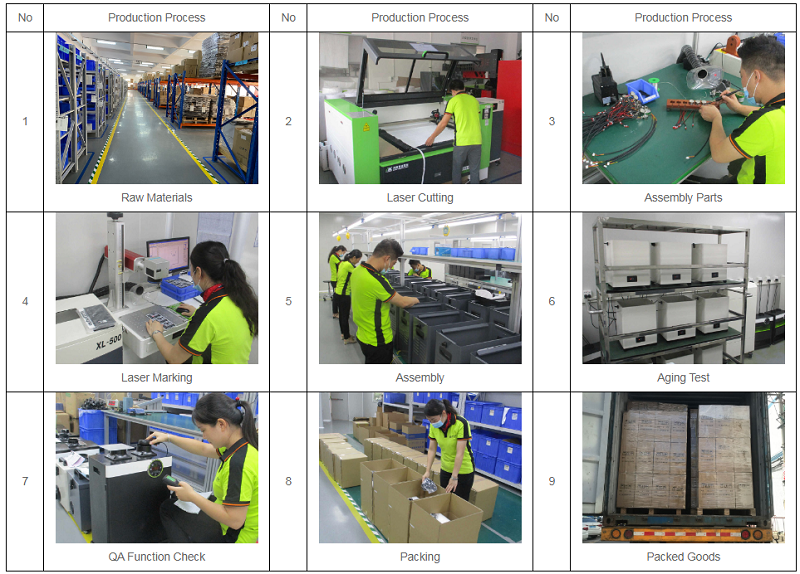

Our products go from design to production to final product. Each working procedure is strictly controlled, we make really effective fume extractors only. The filtering efficiency of our fume extractors has reached the highest standard in the world.

OEM & ODM Services:

We can offer OEM & ODM services. Welcome to talk with us in details.

|