| Sign In | Join Free | My esadidasol.com |

|

| Sign In | Join Free | My esadidasol.com |

|

| Categories | Corrugated Board Cutting Machine |

|---|---|

| Brand Name: | SOOME |

| Model Number: | SMDW-NCGP-2200 |

| Certification: | CE |

| Place of Origin: | Made In China |

| MOQ: | 1 Set |

| Payment Terms: | L/C, T/T, Western Union |

| Delivery Time: | 2 Months |

| Packaging Details: | Wapped With Film |

| Price: | Negotiation |

| Type: | Packaging Line |

| Condition: | New |

| Driven Type: | Electric |

| Power supply: | 380V 50Hz |

| Power: | 90KW |

| Automatic Grade: | Automatic |

Type NC Roll To Sheet Cutting Machine Exquisite Printing Pattern 380V 50Hz

Summarize

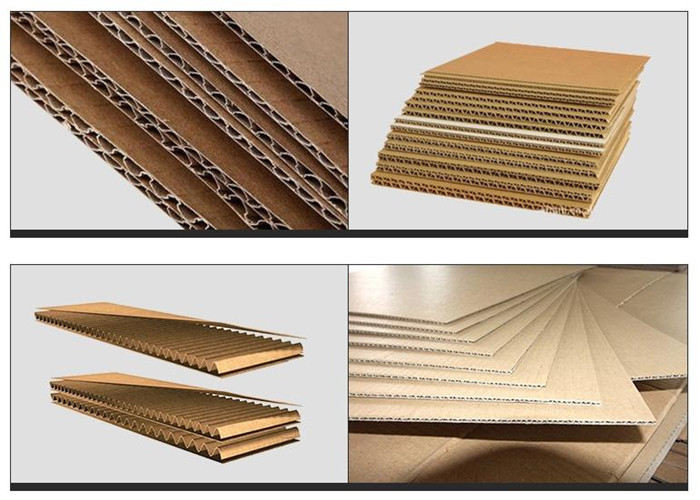

The slitter-cutter machine is one of the important unit of the

corrugated cardboard production line. It is a mechanical equipment

for cutting the finished product of cardboard. Its technical

performance and equipment adjustment not only affect the overall

production speed of the tile line, but also play a vital role in

the size accuracy and external quality of cardboard and cartons. It

is suitable for crosscutting, whiteboard, kraft paper, paper

plastic composite, plastic hard sheet and other reel materials. The

feature uses computer control (automatic length, number alarm,

automatic stop, counting), servo motor (step motor) feed, rear

discharge material, magnetic powder brake, flat knife cut off and

leveling, feed pressure roller (air pressure), automatic deviation

(B) (can be selected according to different materials), frequency

conversion speed regulation; external function: cutting printed

material Material photoelectric tracking (G), which can be selected

from different materials.

Main Technical Parameters

1. Type:WJ-200-2200 single corrugated cardboard production line.

2. Max Produce width:2200mm

3. Design speed:200m/min

4. Economic speed:900-120m/min

5. Note:Production line speed test paper should meet the following requirements:(Equipment surface temperature not lower than 172 ℃ above)

Paper grade of not less than B grade

Paper moisture content of about:11%±2%

Facial tissue:100—250g/m2

Core paper:100--180g/m2

6. Flute-type combination:A ,C, B, E(Or a choice by the customer)

7. Steam about500Kg/Hr; Maximum pressure:1.2Mpa;Common pressure:0.8-1.1Mpa

8. Power supply:380V 50Hz Three-phase four-wire system

9. Equipment installed total power:about 90KW Actual electric consumption:about30KW

10. Equipment area:about 30m×11m×5m(Specific length of foundation Figure prevail)

11. Equipment out of paper orientation:according to user’factory to determine drive left or right

12. Equipment applicability,Available in A, B, C class domestic or imported paper Paper.

|